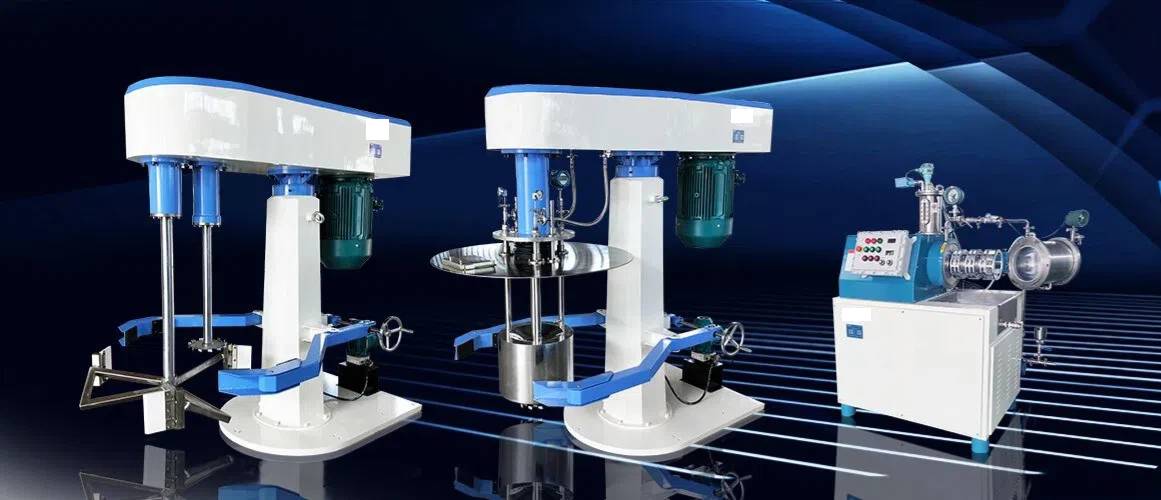

Chemcore deals in high-performance industrial machines used primarily in the paint, ink, coating, and chemical industries for mixing, dispersing, and grinding material.

Our Dispersers are high-speed mixing machines designed to break down agglomerates and disperse solid particles into liquid. They work by applying shear force through a rotating blade or disc, which creates turbulence and ensures uniform dispersion. These machines are widely used for:

- Paints and coatings

- Printing inks

- Adhesives

- Cosmetics

- Pharmaceuticals

- Chemicals

Our dispersers typically come with:

- Vacuum or non-vacuum operation

- Hydraulic or mechanical lifting mechanisms

- Variable speed controls for different viscosities

- Explosion-proof options for volatile materials